What Makes TMT Steel Bars So Highly Flexible Among All Steel Bars?

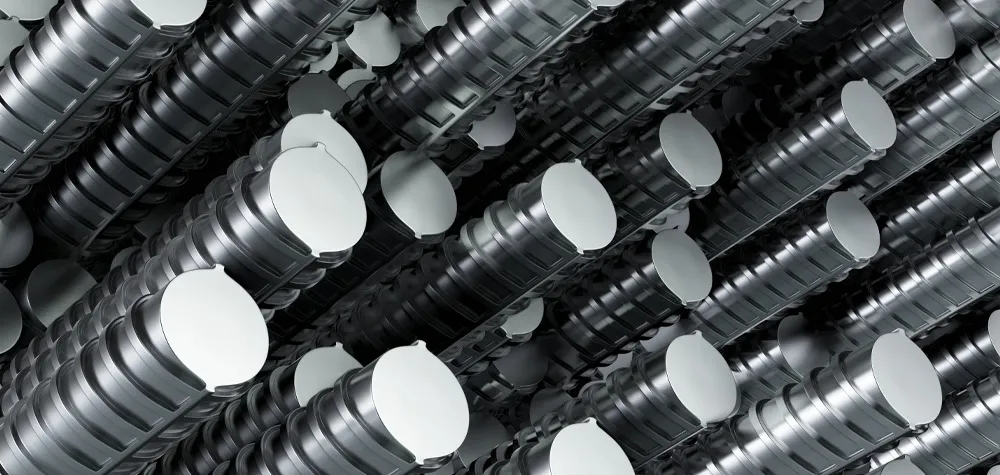

TMT steel bars

TMT steel bars pass through several processes to maintain ductility and flexibility. The method includes Quenching, Self-Tempering, and Atmospheric cooling. Quenching is a process where the TMT bars are cooled down quickly after being hot rolled using a technique called Quenching. This process is done through a water spray system called the Thermex System. The rapid cooling hardens the outer layer of the bars while keeping the core hot, making the bars strong and flexible. This unique cooling technology ensures that the TMT bars have the right balance of strength and flexibility, making them ideal for construction.

The second is self-tempering; after the rebars are quenched in the Thermex system, the core of the bars remains hot while the surface cools down. This temperature difference causes heat to flow from the core to the surface, forming a structure called Tempered Martensite. This structure enhances the strength and toughness of the rebars, making them suitable for construction purposes.

The final process is Atmospheric cooling; they are placed on a cooling bed at normal temperature. During this step, the austenitic core of the bars transforms into a ferrite-pearlite structure. As a result, the final structure of the TMT bars consists of a strong outer layer and a ductile core. This process increases the tensile strength of the bars, making them highly ductile and weldable. Combining a strong outer layer and a ductile core gives TMT bars their desirable mechanical properties for construction applications.

Importance of TMT steel bars:

TMT steel bars are mainly used for construction such as dams, buildings, bridges, and highways and in infrastructure projects such as bridges, tunnels, flyovers, and culverts because they can withstand heavy loads and stresses imposed on them. These bars are used in high-rise buildings to provide strength, flexibility, and stability to support columns, beams, and slabs. These can also support vertical loads and resist horizontal forces such as wind and earthquake.

What makes a TMT steel rod flexible:

TMT bars are flexible because of how they are made. During manufacturing, they are cooled in a particular way that makes the outer part rigid and the inner part flexible. The surface of the bars has small bumps or ridges, which help them stick to concrete better. These bars can stretch long before breaking, so they can handle bending and twisting without cracking. They can also absorb and distribute stress and strain effectively, making them useful in areas prone to earthquakes. Steel bars are designed to have a good balance between strength and flexibility. They are strong enough to carry heavy loads and flexible enough to bend without breaking.

Manufacturing steel is a process that needs an integrated steel plant with superior raw materials, quality quenching, and tempering equipment. Every manufacturing unit should have serious quality control checks. One of the best manufacturers, ARS Steel in Chennai, is known for its durability and long lifespan. These strong bars provide stability and safety in construction and infrastructural projects. They can handle different loads and have a balanced combination of strength and flexibility. ARS Steels has a wide range of raw materials and finished TMT bars in stock, which means they can provide high-quality bars for all construction and infrastructure requirements. They have the best TMT bars available for building homes, offices, dams, bridges, or other structures.