A TRUE PARTNER IN YOUR

PURSUIT OF EXCELLENCE

ARS TMT bars provide unmatched dependability

through superior quality construction materials to bring

your vision to life.

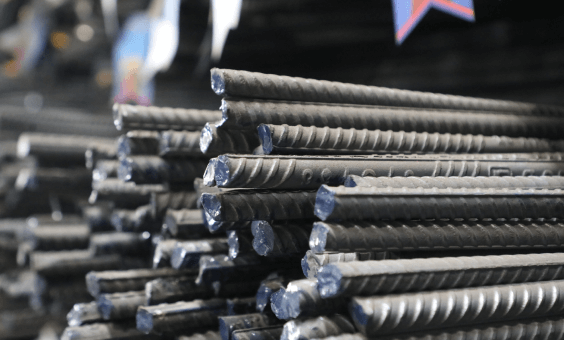

Precise chemical compositions and advanced manufacturing processes are critical in creating steel rods for construction that can be used to build dependable and durable structures. The structural integrity of any building is subjected to immense stresses, which is why the type of steel bars and construction materials need unfailing dependability.

Ensuring the highest quality in construction starts with the precise chemical composition of TMT steel bars. ARS TMT steel bars are crafted using a meticulous selection of elements, optimizing the balance between strength, ductility, and corrosion resistance. This precise formulation guarantees exceptional performance and durability, meeting the stringent demands of engineering projects.

The thermo-mechanical treatment (TMT) process is at the heart of our superior steel production. Through controlled heating and cooling, we enhance the microstructure of our TMT bars, significantly improving their mechanical properties. This advanced process ensures that ARS TMT bars provide the necessary strength and flexibility required for modern construction challenges.

Our quenching process involves rapidly cooling the outer layer of the TMT steel bars while maintaining a softer core. This innovative technique creates a tough, durable surface with high tensile strength, while the flexible core prevents brittleness. The result is a TMT bar that offers unmatched resilience and safety for any construction project.

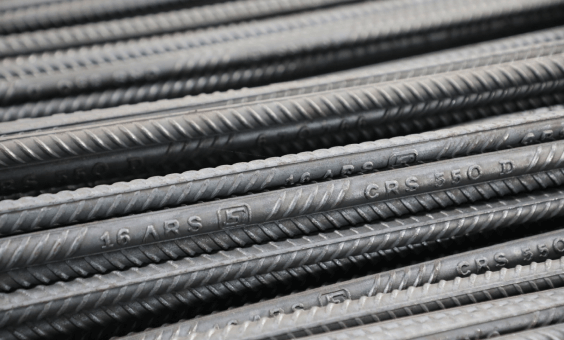

The creation of ribs on our TMT bars is a critical step in enhancing their bonding with concrete. Our precise rib patterns ensure superior grip and anchorage, increasing the overall strength and stability of the structure. This meticulous attention to detail in rib creation contributes to the long-term durability and integrity of your projects.

Our TMT bars feature a distinctive logo mold, a mark of authenticity and quality. This branding not only ensures traceability but also guarantees that you are using genuine ARS TMT bars. The logo mold on ARS TMT steel bars is a testament to our commitment to providing reliable and superior construction materials for engineers and experts.

| Properties | Unit | IS 1786 - Fe 550D | ARS 550D | ARS 550D CRS |

|---|---|---|---|---|

| Yield Strength | N/mm^2 | 550 Min. | 550 Min. | 560 Min. |

| Tensile Strength | N/mm^2 | 600 Min. | 600 Min. | 620 Min. |

| TS/YS | Ratio | 1.08 Min. | 1.1 Min. | 1.08 Min. |

| Elongation | % | 14.5 Min. | 16 Min. | 16 Min. |

| Properties | Unit | IS:1786 Fe-550D | ARS 550D | CRS 550D |

|---|---|---|---|---|

| C | % | 0.25 Max. | 0.25 Max. | 0.25 Max. |

| S | % | 0.04 Max. | 0.04 Max. | 0.04 Max. |

| P | % | 0.04 Max. | 0.04 Max. | 0.04 Max. |

| S+P | % | 0.075 Max. | 0.075 Max. | 0.075 Max. |

| CE | % | 0.42 Max. | 0.42 Max. | - |

| CRE (Cr+Cu+P+Mo+Ni) | % | - | - | 0.45 Min. |

We invite engineers and construction experts to collaborate with us to push the boundaries of quality and innovation in the industry. At ARS Steels, we value your expertise and insights, and are committed to achieving new heights in construction excellence together.

ARS Steel’s latest initiative, the Mobile Steel Patrol, offers an ‘On-road Testing lab’, where engineers and construction experts can understand and verify the rigorous tests that our materials go through at our factory. You can participate in live demonstration of quality testing for TMT rods, and especially, the ARS 550D, at your own construction site.

Our qualified civil engineers are trained to provide technical guidance about the different types of construction materials, and their suitability to your project.Engage in live demonstrations of Bend/ Re-Bend tests (to check for rupture and cracks), and Martensite (Ring) tests for ARS TMT steel bars which verify the hardness, ductility, and strength of steel based on rings formed in the test. You can also watch videos of Multi-Point Testing of our products which conform to the highest standards of safety and durability.

In creating safer, stronger, and more

resilient structures with our products.