Our Quality

Quality Certification By External International Agency (Sgs)

Transparency In Price And Other Commercial Terms

Truly corrosion resistant & ductile

100% "D" Quality

On Time Despatch All Sizes (8mm To 32mm)

Savings (Rs.4000/-per Ton) Certified By SERC

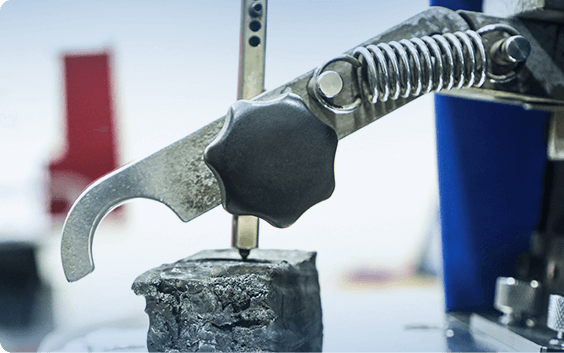

The company always ensures to enhance its customer experience; therefore there are in-house facilities like OES (Optical Emission Spectrometry) and Lab facilities for Macro Analysis of the products. This special quality of ARS 550D TMT bars is also labeled as ARS 550D “Fe 550D”. Here, “Fe” signifies ferrous denoting iron, “550” indicates the minimum yielding strength and “D” indicates ductility. The high ductility amplifies the shock withstanding capacity and makes ARS 550D earthquake and fire resistant up to 500 Degree Celsius. Driven by values, commitment, and a strong urge to deliver the best to its customers, ARS 550D ensures to surpass the quality control specifications enlisted by BIS.