ARS 550D

Know the Truth

ARS has always been striving to achieve excellence and enhance our elaborated product arsenal. To achieve the same, we keep introducing brilliant additions to our evolving product line. It is the result of company’s sustained peak performance, strong leadership, commitment and determination that ARS 550D has emerged as one of the best TMT Bars manufacturers and suppliers in South India.

“Assured Savings of 4% to 6% in TMT Consumption, Certified by SERC, A Leading Central Government Research Firm. Consistent Production of 100% “D” quality product (i.e Low Sulphur and Low Phosphorous)

SGS, an Swiss based European Testing agency tests every batch for quality and only Certified products are despatched.

BIS Certification to further ensure the Product standard.

ARS 550D TMT are manufactured using high grade raw material, sourced domestically and internationally.

Due to high ductile property, ARS 550D TMT bars has increased shock withstanding capacity.

ARS 550D TMT bars aids in more safer, stronger and secured foundation for Skyscrapers, Reservoirs, Expressways, Bridges, Residential Complexes and other Industrial & Domestic structures.”

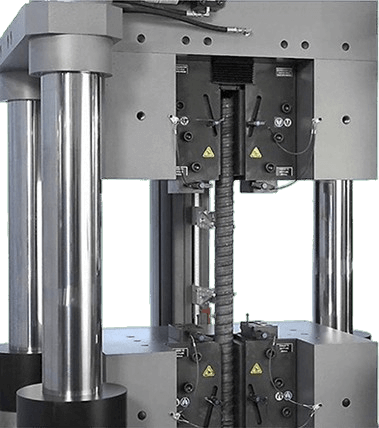

ARS 550D TMT Bars are expertly manufactured using superior quality raw materials to fulfill the requirements of the Infrastructure industry. The new-engineered design with exclusive vertical and horizontal lugs provides exceptional concrete-steel powerbond. Fortified with high yield stress, shock resistance and elongation properties, ARS 550D TMT Bars provided maximum earthquake and corrosion resistance. The use of ARS 550D TMT Bars leads to maximum savings in steel in terms of weight and cost. ARS 550D is undeniably the foremost preference of construction industry. It is here to build the foundation of a strong, sustainable future and revolutionize the infrastructural landscape of the country.

| Properties | Unit | IS 1786 - Fe 550D | ARS 550D | ARS 550D CRS |

|---|---|---|---|---|

| Yield Strength | N/mm^2 | 550 Min. | 550 Min. | 560 Min. |

| Tensile Strength | N/mm^2 | 600 Min. | 600 Min. | 620 Min. |

| TS/YS | Ratio | 1.08 Min. | 1.1 Min. | 1.08 Min. |

| Elongation | % | 14.5 Min. | 16 Min. | 16 Min. |

| Properties | Unit | IS:1786 Fe-550D | ARS 550D | CRS 550D |

|---|---|---|---|---|

| C | % | 0.25 Max. | 0.25 Max. | 0.25 Max. |

| S | % | 0.04 Max. | 0.04 Max. | 0.04 Max. |

| P | % | 0.04 Max. | 0.04 Max. | 0.04 Max. |

| S+P | % | 0.075 Max. | 0.075 Max. | 0.075 Max. |

| CE | % | 0.42 Max. | 0.42 Max. | - |

| CRE (Cr+Cu+P+Mo+Ni) | % | - | - | 0.45 Min. |

Thermo-Mechanical Treatment (TMT), is a metallurgical process that integrates work hardening and heat-treatment into a single process.

Since TMT bars undergo thermo-mechanical treatment, they are extremely ductile and have high tensile strength. This makes it usable for every shape. It also provides great resistance to fire, earthquake, and corrosion. It is also easy to transport because of its lightweight build.

TMT bars are divided into various grades – Fe415, Fe500, Fe500D, Fe550 and Fe600. The number denotes the yield strength of the TMT bars and the letter ‘D’ denotes the ductility. Each grade has different properties and applications and therefore it is important to choose the right grade by knowing its application and usage.

TMT bar which contains a higher amount of Sulphur makes it prone to fire and a high amount of phosphorus causes fatigue to the bars.

Often due to the interaction of the rebar with moisture and air, the surface of the rebar develops a reddish colour which is being misunderstood as corrosion. Reddish rebar can be used for construction without any hesitation as long as they are in proper physical shape, weight and strength.

Please complete this form with basic information you need.