Difference Between Corrosion Resistant Steel and Regular Steel

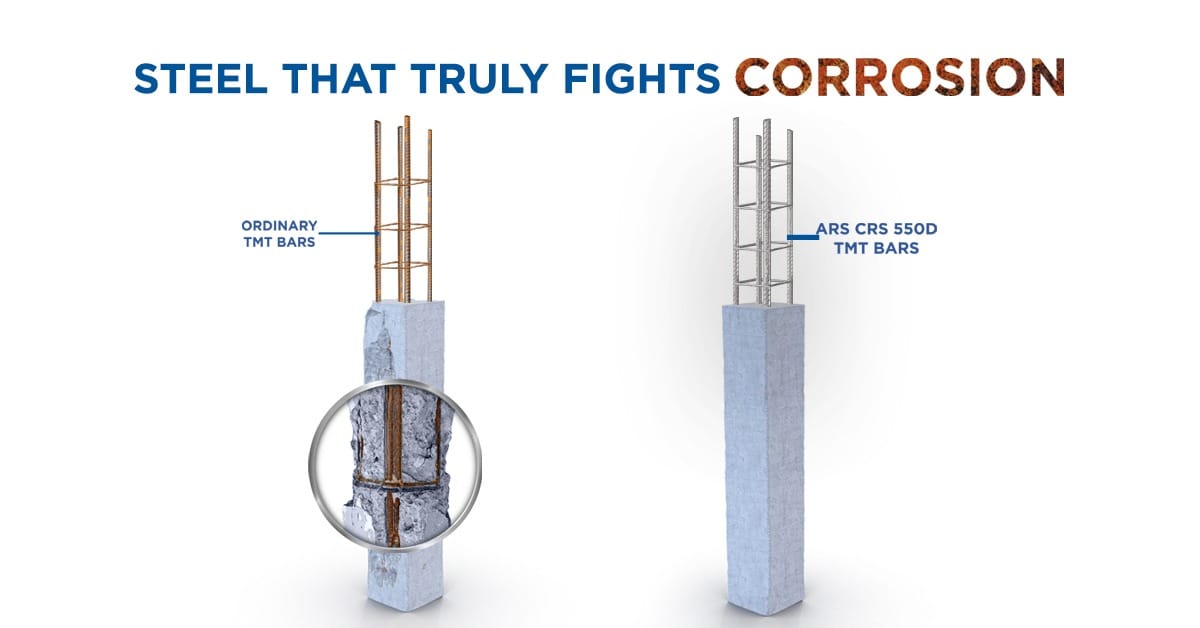

Steel is one of the critical materials used in construction, manufacturing, and engineering. Known for its due to its strength and durability, steel however suffers from a serious challenge – Corrosion. Steel corrosion is the gradual deterioration of steel when the iron in the metal oxidises. Over time, this can weaken the material, leading to structural issues and increased maintenance costs. To combat this, TMT bar manufacturers have developed corrosion resistant steel (CRS), which can effectively fight corrosion and assure longevity for the structure.

In this blog, we’ll explore what is steel, what is corrosion resistant steel, and the key differences between these two materials.

What is Steel?

Steel is an alloy of iron and carbon. It provides superior strength and fracture resistance compared to other forms of iron. It may also contain additional elements like chromium, manganese, and silicon. Due to its high tensile strength, durability, and relatively low cost, steel is widely used in buildings, infrastructure, automobiles, machinery and so on. Steel can also be recycled without losing its properties, making it sustainable and versatile.

What is Corrosion Resistant Steel?

Corrosion resistant steel (CRS) is a type of steel specifically designed to resist corrosion, even when exposed to adverse conditions. By incorporating elements such as chromium, copper, and nickel into its composition. These alloys form a protective oxide layer on the surface, thereby preventing corrosion. This unique property makes them highly resistant to rust, tarnishing, and staining, even in harsh environment.

The concept behind corrosion resistant steel is to extend the material’s longevity, reduce maintenance cost, and offer better performance in challenging conditions.

Key Differences Between Regular Steel and Corrosion Resistant Steel

1. Composition

• Regular Steel: Made primarily of iron and carbon, with minimal additives. It is prone to rust when exposed to moisture and oxygen.

• Corrosion Resistant Steel: Contains additional elements like chromium, copper, and nickel. These additives help in forming a stable oxide layer, which protects the steel from rusting.

2. Resistance to Environmental Factors

• Regular Steel: Highly susceptible to corrosion when exposed to humid or salty environments.

• Corrosion Resistant Steel: Designed to withstand harsh conditions, such as marine environments or industrial settings with high humidity.

3. Durability

• Regular Steel: Requires regular maintenance, painting, or coating to prevent corrosion.

• Corrosion Resistant Steel: Has a significantly longer lifespan with minimal upkeep, making it a cost-effective choice in the long run.

4. Applications

• Regular Steel: Used in applications where exposure to corrosive environments is minimal, such as interior structures or low-stress environments.

• Corrosion Resistant Steel: Commonly used in bridges, marine equipment, oil rigs, and chemical plants where resistance to corrosion is critical.

CRS Steel Specifications

CRS steel specifications vary depending on the grade and intended use. Some key standards include:

• Chemical Composition: Highest Corrosion Resistance Equivalent (CRE) average of 0.5% Min

• Mechanical Properties: High tensile strength, highest bonding with concrete, higher fire resistance.

• Environmental Performance: Resistance to pitting, crevice corrosion, and stress corrosion cracking.

Why Choose Corrosion Resistant Steel?

• Performance: Ideal for coastal areas, suitable for construction where high water salinity

• Enhanced Safety: CRS steel maintains its structural integrity over time, reducing the risk of failures in critical applications.

• Eco-Friendly: With longer durability and less frequent replacements, CRS steel contributes to sustainability by reducing resource consumption.

Conclusion

While regular steel is suitable for general applications, corrosion resistant steel is indispensable in environments prone to corrosion. The protective properties of CRS steel ensure a longer lifespan, reduced maintenance, and improved performance in challenging conditions. By understanding what is steel and what is corrosion resistant steel, consumers can make informed choices, optimizing costs and ensuring durability.

If you’re considering CRS steel for your next project, understanding CRS steel specifications will help you choose the most suitable grade for construction. Choosing corrosion resistant steel is not just a step toward better construction but also a leap toward sustainability and efficiency.