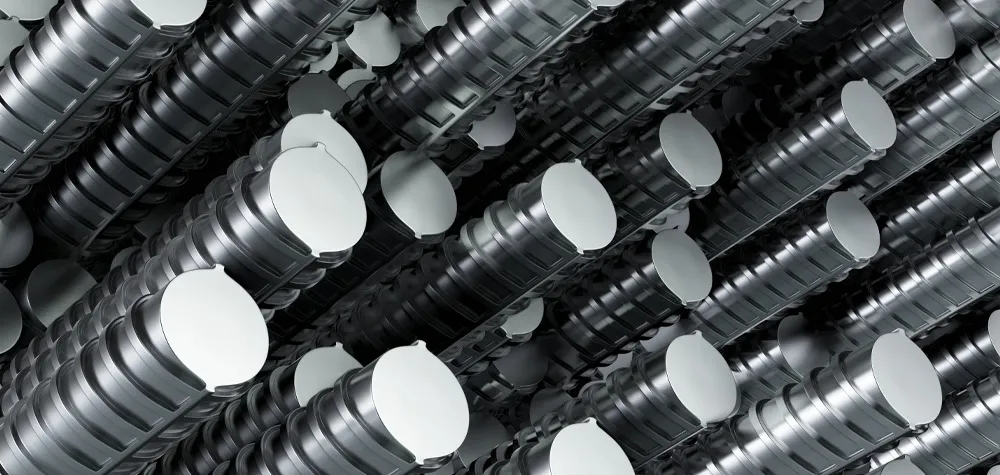

Exploring different types of TMT steel bars used in construction.

In the context of construction, the selection of suitable building materials plays a pivotal role in ensuring the durability and strength of structures. One such essential component is TMT steel bars, also known as TMT bars, generally found among steel rods for construction. These bars provide crucial support and reinforcement to concrete structures, making them indispensable in the construction industry. In this article, we will delve into the different types of TMT steel bars used in construction, highlighting their distinct characteristics and applications.

Mild Steel TMT Bars:

Mild steel TMT bars are the most commonly used type of steel bars in construction projects. They possess excellent weldability and ductility, making them easy to work with and shape according to construction requirements. These bars are ideal for small to medium-scale construction projects, where moderate strength and flexibility are necessary.

High-Strength TMT Bar:

As the name suggests, high-strength TMT bars are specifically designed to offer superior strength and toughness. These bars are manufactured with advanced technology and undergo a controlled quenching and tempering process. This creates it’s enhanced mechanical properties.

High-strength TMT bars are typically utilized in large-scale construction projects such as bridges, high-rise buildings, and infrastructure projects that require exceptional structural stability and load-bearing capacity of steel rods for construction.

Corrosion-Resistant TMT Bars:

In environments where corrosion is a concern, corrosion-resistant TMT bars prove to be an excellent choice. These bars are manufactured with a special corrosion-resistant coating that shields them from rust and other forms of corrosion. As a result, they are ideal for construction projects in coastal areas or regions with high humidity levels, where exposure to moisture is a common occurrence.

Fire-Resistant TMT Bars:

Safety is paramount in construction, especially when it comes to fire hazards. Fire-resistant TMT bars are designed to withstand high temperatures. It provides an increased level of fire resistance to structures. These bars are manufactured with an additional layer of protection that prevents them from losing their structural integrity. In the event of a fire, they ensure the safety of the building and its occupants.

Earthquake-Resistant TMT Bars:

In seismic zones or areas prone to earthquakes, the use of earthquake-resistant TMT bar becomes crucial. These steel bars for construction possess excellent flexibility and can absorb and dissipateseismic energy, minimizing the risk of structural damage during earthquakes. The unique composition and manufacturing process of these bars make them indispensable in regions where seismic activities are common.

The type of steel bar that is used the most frequently in modern construction is TMT steel.In addition to having unmatched tensile stress, TMT steel possesses several traits and characteristics that standard steel bars do not.TMT steel is easy to use, corrosion-resistant, earthquake-resistant, and compact. In actuality, the TMT steel is the best available option for clients today due to its production process.You can choose the TMT steel sub-variety that best suits your needs from several sub-varieties that have different qualities and strengths.

TMT steel bars, available in various types and grades, have revolutionized the construction industry with their superior strength, durability, and specialized properties. Whether it is mild steel TMT bars for smaller projects, high-strength bars for large-scale structures, or corrosion, fire, and earthquake-resistant bars for specific environmental conditions, the versatility of TMT bars ensures the safety and longevity of steel rods for constructions.

In conclusion, it is essential to select the appropriate type of TMT steel bars that align with the project’s requirements and the environmental conditions in which they will be utilised.