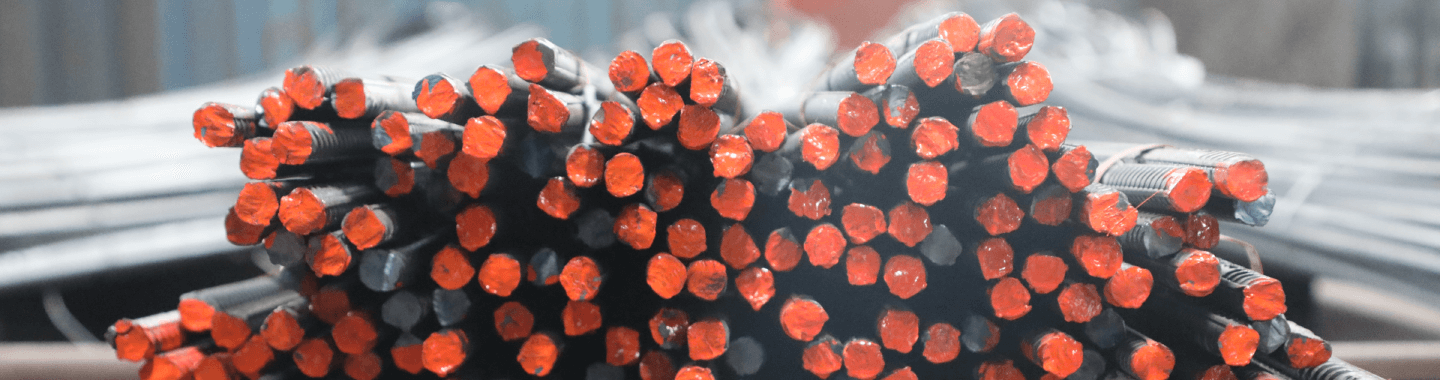

Unveiling the Strength: Exploring the 8mm, 10mm, 12mm, and 16mm TMT Steel Bars

Steel bars are an essential component in construction projects, providing high ductility and reinforcing bonding with concrete. Among the various sizes available, 8mm, 10mm, 12mm, and 16mm steel bars are commonly used. In this blog post, we will delve into the type differences of these different sizes and explore their implications in architectural design.

Understanding Steel Bars

Steel bars, also known as reinforcing bars or rebars, are typically made from carbon steel and are used to enhance the tensile strength of concrete structures using specific quantities of Sulphur and Phosphorus combinations. They come in various sizes, each with its own weight and load-bearing capacity and must satisfy the IS 1786 – 2008 physical and chemical standards.

The Mighty 8mm Steel Rod

The 8mm steel rod is a popular choice in architectural projects due to its versatility, superior elongation, and cost-effectiveness. It is lightweight, making it suitable for applications that don’t require heavy loads. Its smaller diameter also makes it easier to handle during construction.

Unveiling the 10mm Steel Rod

Slightly larger than the 8mm counterpart, the 10mm steel rod offers increased strength and load-bearing capacity. It is often used in projects that require moderate reinforcement. Architects value this size for its balance between strength and higher ductility.

The Sturdy 12mm Steel Rod

For projects that demand higher structural integrity, the 12mm steel rod comes into play. It offers enhanced strength and durability. Architects rely on this size for constructing robust structures that can withstand heavy loads and external forces suitable for projects ranging from individual and large-scale houses.

Exploring the Power of 16mm Steel Rods

When it comes to heavy-duty construction, the 16mm steel rod takes the centre stage. This size offers exceptional strength and load-bearing capacity. It finds its application in large-scale projects such as high-rise buildings and bridges, where structural stability is of utmost importance.

In conclusion, the weight variations of 8mm, 10mm, 12mm, and 16mm steel bars play a crucial role in architectural design. The selection of the appropriate size depends on the specific requirements of the project, considering factors such as load-bearing capacity, structural integrity, and cost-effectiveness. By understanding the weight differences and their implications, architects can make informed decisions to ensure the success and longevity of their constructions. Because constructing is a large undertaking, selecting the appropriate TMT bar with certifications and quality criteria is essential. One of the highest-quality steels, certified by SGS, on the market right now is ARS 550D TMT with bars manufactured for a variety of end uses. ARS 550D TMT bars are the primary choice for both small and large building projects while also providing round the clock service and a free Spectro-van testing facility.