How to choose tmt bars

When it comes to constructing durable and safe structures, selecting the right materials is of paramount importance.

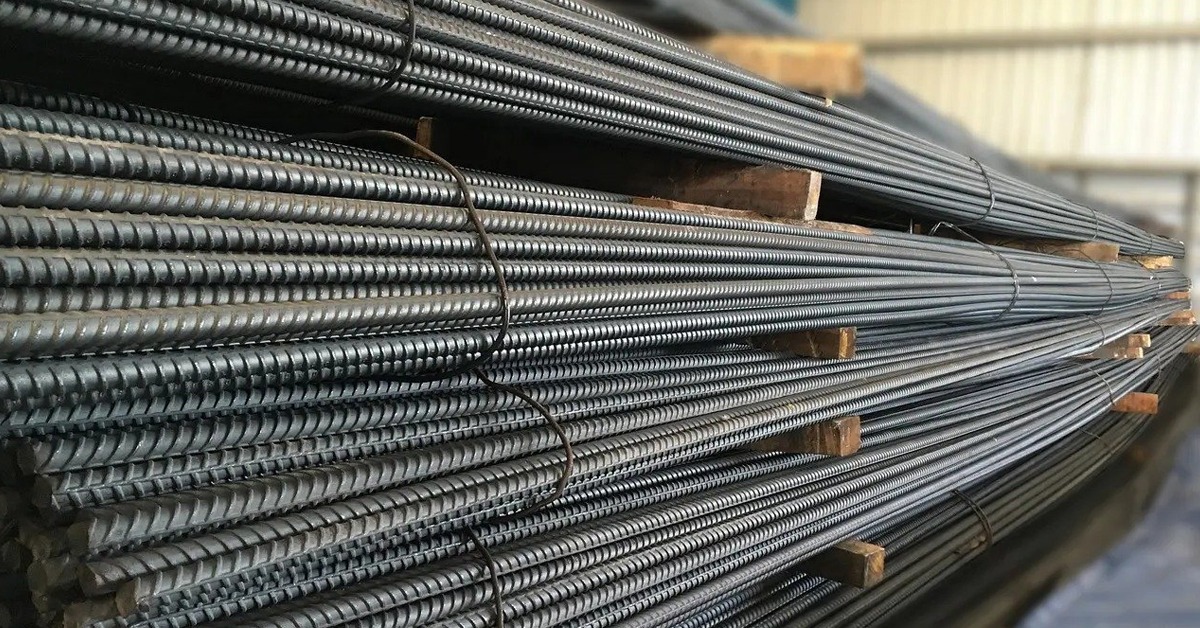

TMT Steel bars have become the preferred choice for reinforcing concrete in the construction industry due to their exceptional properties from Thermo-Mechanical Treatment.

These TMT Steel bars undergo a specialized manufacturing process involving Quenching “Thermex” Technology where ductility and yield strength is being obtained as per IS code simultaneously, which imparts superior strength and ductility, making TMT Steel bars ideal for withstanding heavy loads and seismic forces.

Spectro meter Testing is employed to precisely analyse the chemical composition of the bars, ensuring optimal strength, durability, and corrosion resistance.

ARS Steel, a leading brand in the industry, is committed to delivering the best TMT bars, backed by their exceptional Spectro meter testing capability.

This technology not only guarantees best TMT steel bars but also provides valuable data for quality control, certification processes, and customer confidence.

How to choose Best TMT Bars?

When choosing TMT bars, several factors need consideration:

Grade of TMT Bars: TMT bars come in various grades denoting their minimum yield strength. Higher grades like Fe-500, Fe-550 and Fe- 550D with high strength and ductility are commonly used for highly durable structures.

Certification: Steel products should be certified by reputable organizations like SGS to ensure they meet specific quality standards, regulatory requirements, and undergo rigorous testing and inspection. Certification also promotes consistency, transparency, and accountability in the industry.

Impurity Concerns: Impure steel can compromise the structural integrity of constructions, posing safety hazards. ARS Steel stands out in the market by prioritizing purity and quality, adhering to strict quality control measures to deliver steel products free from impurities. One of the main drawbacks of impure steel is compromised structural integrity. Impurities can weaken the steel, leading to potential safety hazards in construction projects and infrastructure. This emphasizes the importance of rigorous quality control measures to identify and eliminate impurities before the steel reaches the market.

The presence of impurity in steel is a pervasive challenge. However, amidst this concern, ARS Steel emerges as a brand that prioritizes purity and quality above all else in a best TMT steel price market can offer. Choosing ARS Steel for steel requirements ensures the assurance of purity and quality, setting them apart in the industry. Their commitment to excellence and adherence to industry standards make them a reliable choice for any construction project.

Conclusion:

In conclusion, selecting the right TMT bars is essential for building long-lasting structures. While TMT steel prices are important considerations, it is crucial to prioritize the quality, reliability, and purity of the bars. Investing in high-quality TMT bars ensures structural durability. ARS Steel, with its unwavering commitment to quality, provides customers with reliable steel products that meet and exceed industry standards.

- Fe 550D steel with 550 Yield strength with good ductility.

- Chemically and physically tested.

- SGS certified.

- Purity as per IS 1786 – 2008.

Their dedication to purity and excellence establishes a reputation for reliability and long-lasting performance, making them a standout choice in the market.